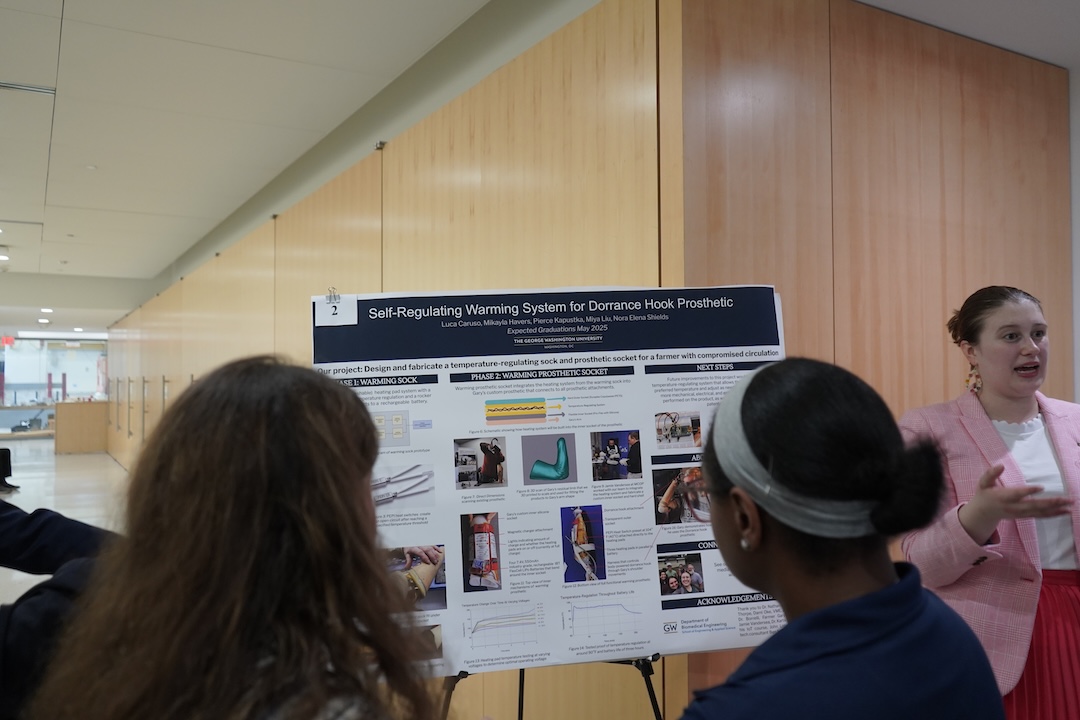

Warming All-Purpose Sock and Prosthetic (WAPSAP)

Project Team

Luca Caruso

Mikayla Havers

Pierce Kapustka

Miya Liu

Nora Elena Shields

Project Sponsor(s)

Angela Tyler, Volunteers for Medical Engineering (VME)

Project Mentor(s)

Dr. James Borrelli, Stevenson University, VME

Jamie Vandersea, Medical Center Orthotics and Prosthetics

Michael Raphael, Direct Dimensions

Samuel Simonetta, Direct Dimensions

Instructor(s)

Dr. HyungSok Choe, BME, GW Engineering

Dr. Steven Shooter, MAE, GW Engineering

Gary is a 67-year-old amputee patient from Maryland who uses a body-powered prosthetic for his self-sustaining farming business. Due to his compromised circulation, he experiences significant cold discomfort – even in moderate weather. Our two medical devices work together to solve for Gary's discomfort by ensuring that his residual limb remains at a comfortable temperature at all times. Our first device - a warming sock - is for Gary to wear around the house or in less physically intense scenarios. Our second device - a warming prosthetic socket - is designed for Gary to use while working outside during any season. The prosthetic socket addresses several key design requirements which were specifically requested by Gary: maintaining a temperature from 30 ℃ to 40 ℃ for four hours, recharging in an hour, being secure and durable without restricting movement, avoiding direct skin contact, and incorporating an on/off switch for user control.

Who experiences the problem?

There are 5.6 million individuals in the United States who have limb loss or limb difference. From the prosthetics experts that we worked with on this project, we gained an understanding that decreased circulation is common for someone who has lost a limb. An additional factor in who experiences this problem is age. As a person ages, there is a decrease in circulation and other heart and blood-related complications.

Why is it important?

The prosthetic market prioritizes profit-driven innovations, which often results in overlooking simple and affordable solutions. Considering how many people rely on this market to help them survive in a world that is built for able-bodied people, the gap in enterprise-centered versus patient-centered design is evident. When we first met Project Mentor, Jamie Vandersea, he told us a body-powered prosthetic socket alone costs between $6000 and $8000 for someone to purchase. Therefore, there is a need and opportunity for designs that are both accessible and highly tailored to the patients, which makes addressing this problem very important.

What is the coolest thing about your project?

The coolest thing about our project is that we found a simplified way to integrate a heating system into a prosthetic socket. Current options on the market are either only cooling systems or require prosthetic experts to integrate into the sock in a way that is not disclosed to the patient. Our design is encompassed in a clear plastic outer socket, so anyone can literally see every component and how they're connected.

What sustainable design considerations drove your solution?

Gary is very passionate about the environment and sustainability, so making sustainable design choices was a significant part of certain aspects of our design process. For both the sock and the prosthetic socket, we specifically opted to use rechargeable batteries. The sock uses a Lithium Polymer (LiPo) battery that will last approximately 300 charging cycles before starting to decline in performance and needing to be entirely replaced. The socket uses Flex Cell batteries, which are thin flexible batteries that are relatively pressure-sensitive and will last 2-3 years before needing to be replaced. Another sustainable design consideration was ensuring the warming sock can be washed without damaging the electronics; by utilizing Velcro as opposed to a more permanent fastening method (i.e. sewing), Gary is able to wash the sock as needed – it stays fresh without needing to worry about ruining it.

What were some technical challenges?

We had several technical challenges, which are detailed below. Gary had very specific requests regarding the size and placement of the battery for the warming sock. He wanted a microbattery that fit in a very specific location on his forearm, but this was not feasible because a small battery cannot power the heating system we chose to use. We eventually discovered the rechargeable LiPo as a good alternative that Gary also liked, but getting to that point was a difficult process. As for the socket, we got to completely eliminate this problem as a result of being able to integrate the Flex Cell batteries into the actual socket as opposed to on Gary’s arm.