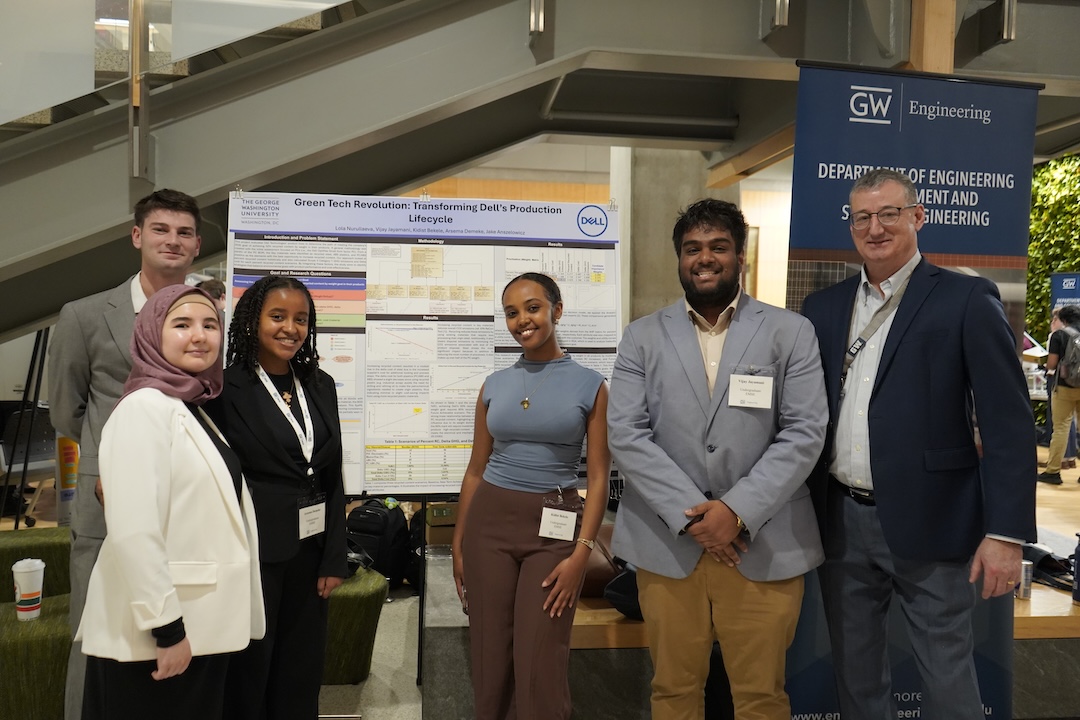

Green Tech Revolution: Transforming Dell’s Production Lifecycle

Team Members:

Jake Anszelowicz

Kidist Bekele

Arsema Demeke

Lola Nurullaeva

Vijay Jayamani

Team Sponsor:

Dell Technologies

Instructor(s):

Dr. Eric Dano, EMSE, GW Engineering

This project aims to optimize Dell’s material selection process by balancing greenhouse gas (GHG) emissions, cost, weight, and recyclability to support their 50% recycled content goal. It integrates GHG emissions modeling, cost analysis, and weight assessments into a System Modeling (SysML) framework to evaluate trade-offs. A GHG model quantifies the change in carbon dioxide equivalent (CO2E) emissions, capturing the impact of increased recycled content on mining, refining, and disposal emissions. A cost model ensures feasibility, while a weight analysis maintains product constraints. Additionally, an analytic hierarchy process (AHP) survey gathers stakeholder input to prioritize these factors. The final deliverable is a decision-support tool that helps Dell Technologies make data-driven sustainability choices.

Who experiences this problem in the world?

The problem is experienced by electronics manufacturers, policymakers, and consumers worldwide, as a lot of companies face increasing pressure to reduce carbon footprints and meet sustainability goals while maintaining cost efficiency and product performance. Governments and regulatory bodies enforce stricter environmental policies, requiring manufacturers to track and reduce Scope 3 emissions. Consumers are also demanding eco-friendly products, pushing companies like Dell to optimize material sourcing, recyclability, and emissions reduction. Additionally, supply chain disruptions and resource scarcity make it crucial for businesses to find sustainable and cost-effective alternatives for raw materials.

Why is this problem important?

The problem is important because electronics manufacturing significantly contributes to global GHG emissions and waste generation. As companies like Dell work toward sustainability goals, optimizing recycled material use, reducing emissions, and balancing costs is critical to minimizing environmental impact. Addressing this issue helps reduce reliance on virgin materials, lower Scope 3 emissions, and support a circular economy, where materials are continuously reused instead of discarded. Additionally, with regulatory pressures, consumer demand for sustainable products, and corporate responsibility commitments, solving this problem ensures long-term business viability and environmental sustainability.

What is the coolest thing about your project?

The coolest thing about this project is its data-driven approach to sustainability, combining GHG emissions modeling, cost analysis, and recyclability assessments into a comprehensive decision-support tool. Instead of relying on sustainability estimates, the project quantifies the real impact of using recycled materials, helping Dell make informed trade-offs between emissions, cost, and product performance. The integration of SysML modeling and scenario analysis is an interesting and valuable experience we are getting for our future career.

What sustainable design considerations drove your solution?

Sustainable design considerations are at the core of this project, driving the development of a data-driven framework for optimizing recycled material use in Dell’s products. The project focuses on reducing Scope 3 emissions by analyzing how increasing recycled content affects GHG emissions, cost, and producibility. By incorporating industry data, life cycle assessment principles, and circular economy strategies, the project supports Dell’s long-term sustainability goals while maintaining cost efficiency and product integrity.